Home > Products > Foaming Characteristics: Foam Tester

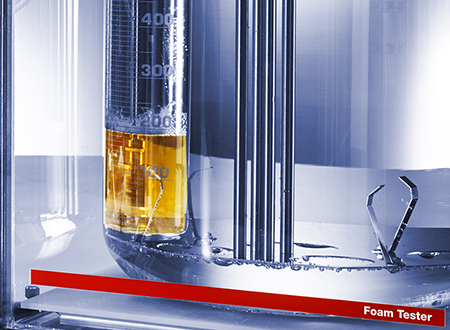

The foam tester allows the determination of the foaming characteristics of lubricating oils at specific temperatures by empirically rating the foaming tendency and the foam stability.

Especially in high-speed gearing and high-volume pumping systems, the tendency of oils to foam can lead to inadequate lubrication or cavitation which may result in mechanical failure.

Key Features

Benefits at a Glance

- Available as twin-bath arrangement

- Four test places in each bath

- Temperature of each bath can be maintained individually

Convenient Operation

- Digitally-indicating circulation thermostats with cooling coil, temperature probe and self-optimizing electronic heating control

- Borosilicate jars (20 L) with leakage protection vessels

- Test equipment for 2 test places per bath included

Customized User Flexibility

- Different gas diffusers: cylindrical-shaped (included) and ball-shaped (optional)

- Test set ASTM D6082 sequence IV (optional)

- Air-drying tower (optional)

- Diffuser stone test set (optional) to check the maximum pore diameter and permeability

- Air-volume test sets (optional) to check the total air-flow rate

- Upgrade kit (optional) to use all 8 test places simultaneously

Technical Specifications

| Application range | 24 °C to 150 °C |

|---|---|

| Test places | 1 to 8 |

| Flow meter range | 0.4 L/h to 7 L/h |

| Air supply | 94 mL/min or 200 mL/min |

| Safety | Overheat and low-level protection, leakage protection vessel |

| Power supply | 115 V or 230 V, 50 Hz/60 Hz |

| Dimensions (W x D x H) | 325 mm x 325 mm x 625 mm (per bath) |

| Weight | 50 kg (twin-bath arrangement) |